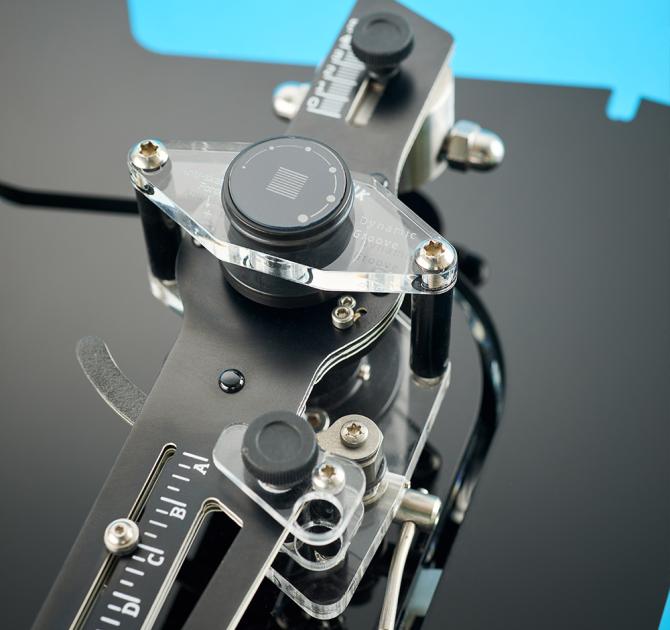

Vertere DG-1S Dynamic Groove Turntable

The DG-1S improvements bring higher resolution replay, greater dynamic contrasts, improved stereo separation with greater precision while at the same time keeping the musicality the DG-1 delivers.

Everything has been redesigned and re-engineered, fromt he plinth to the arm and its bearings developing some of the basic principles of a record-playing system while completely rethinking others.

The result is an elegant turntable that looks like no other. It draws on the engineering of the reference models to deliver outstanding performance and ease of operation at a newly affordable price.

Improved platter bearing

The precision machining and polishing operations have a higher tolerance with the variation halved statistically. The super smooth finish bore with the precision Tungsten Carbine interferene fit ball delivers lower noise, lower rumble, a lower effort for the motor and less rotational variability.

Groove runner S tonearm

The arm beam is now constructed from a five-layer polymer laminate bonded to a second five-layer polymer laminate. The PCB flex signal carrier is bonded in-between the two laminates. The profile of the arm and bearing has improved the counterweight/ bearing/ headshell/ cartridge alignment.

Improved tonearm bearings

The vertical kevlar thread bearing is now adjustable for tension and azimuth. The horizontal nylon thread bearing is now fitted with greater precision to ensure even greater consistency.

New motor drive software

Allows separate adjustment in two steps, initially the sine wave voltage and then the cosine wave adjustment at the final stage for the absolute lowest noise and vibration.

Improved coupling between the three plinths

Improves resistive damping and reduces noise.

The Motor

The motor is the most crucial part of any turntable: it's the only source of energy for the signal generated by the cartridge and fed out to the amplifier, so quality and accuracy are vital. The DG-1 motor system is derived from that developed for the flagship RG-1 Reference Motor Drive: it uses themost advanced motor drive, delivering the best possible performance. The motor itself is a low voltage 24-pole Precision Synchronous design, individually tuned for the lowest noise and with an offboard power supply. An addressable microprocessor PCB controls it during manufacture to ensure accuracy and programmability for future upgrades. A copper and stainless-steelcover provides shielding from both inward and outward interference.

The Platter assembly

Drive to the platter is via a precision machined aluminium alloy pulley on the motor and a bespoke silicon rubber drive belt, with electronic speed change for ease of use. The platter is also aprecision machined alloy, bonded to a PETG record interface mat, and, on the underside, acork/Neoprene/nitrile disk bonded to control platter resonance.

The Bearing

The platter fits onto a super polished stainless-steel spindle that rides in the main bearing housing on a super precision tungsten carbide ball. The complete main bearing assembly is long-term lubricated for longevity and ease of use. This avoids regular repeated recharging of the bearing lubricant, which is essential to prevent premature wear and damage—another example of simplifying this turntable to optimise performance.In addition, the new super-precision bearing delivers lower noise, lower rumble and lower rotational variability.

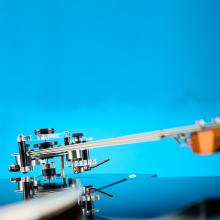

The Groove Runner S Arm

The DG-1 S arm is uniquely Vertere and differs from conventional thinking in its use of a flat profile inplace of the usual tube. Conventional arms use tubes for stiffness, but these can bring all kinds of problems with high Q resonances and thus the need for critical damping–costly and complicated.The DG-1's bonded double five-layer, non-resonant tonearm beam avoids these problems. In addition, in place of conventional tonearm cabling, a flexible PCB is sandwiched into the arm to carry the signal from the cartridge to the output terminals. Completing the arm are a stainless-steel counterweight with azimuth adjustment and a fine adjustment tracking weight, giving a total solution that's as simple and elegant as it is innovative.

Thread Bearings

Many solutions have been sought over the years for precise bearings, but for the DG-1,Vertere has developed a very simple solution: twisted nylon (hundreds of 3 microns thick twined Nylon 6.6/6strands) and Kevlar threads–one for movement in the horizontal plane, and two Kevlar for the vertical axis. These threads have many advantages, not the least of which is simplicity: they exhibit none of the Stiction–or initial resistance to movement–of conventional bearings, are super-light and noiseless, and the twist of the thread controls and damps the movement of the arm.

The Plinth

Like the tonearm, the DG-1 plinth is a sandwich construction, using non-resonant cast acrylic to form the main plinth and the sub-plinth for a clean and sophisticated look. This three-layer design incorporates the control button, the speed indicator and the user-selectable standby mood-lighting, as well as the silicon rubber isolation between the plinth and the platter assembly. The whole assembly sits on a steel chassis, chosen for optimal stability, housing the motor drive circuit and the motor, all supported by three new-design adjustable feet with Resistive Felt Pads.

The DG-1 S comes with a non-resonant Polycarbonate dust cover, where its hinges are integrated into the plinths for a sleek and modern profile.

Available Options:

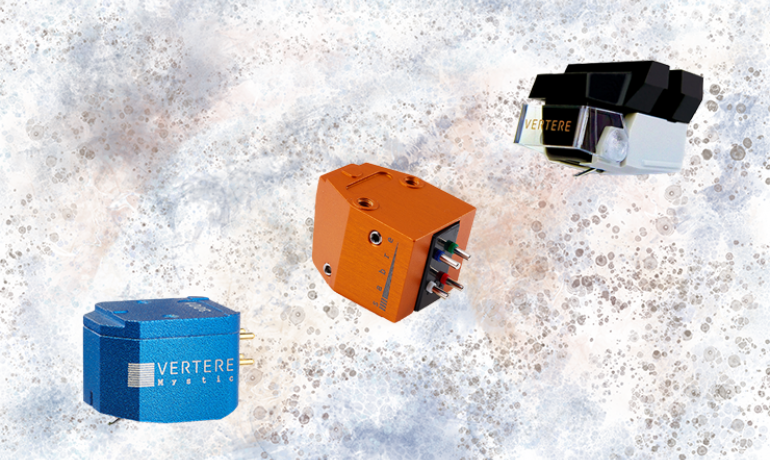

- Standard: with no cartridge - simply a DG-1S with GrooveRunnerS Tonearm

- Magneto Pack: with factory fitted Magneto MM Cartridge

- Sabre Pack: with the Sabre High-End MM cartridge - including stylus bal. technomat & Redline Interconnect Cable

- Dark Sabre Pack: with the Dark Sabre MM cartridge, Challenger Power Supply, Redline Interconnect Cable, stylus balance and technomat

- advanced, improved, microprocessor-generated electronic motor drive for the best possible drive

- fully programmable and copper/stainless steel shielded Motor Drive PCB–allowing forfuture upgrades

- low voltage 24 Pole Precision Synchronous Motor, with its dedicatedmotor drivesupplyprecisely adjusted for lowest motor noise and vibration

- improved super-accuracy polished stainless steel, high aspect ratio, main bearing spindle andmain bearing housing with Tungsten Carbide super-precision Ball

- high precision CNC machined aluminium alloy drive pulley

- high Precision Machined Aluminium Alloy Platter with bonded PETG Record Interface Matand Cork/Neoprene/Nitrile bonded undersideplusresonance control disk

- noiseless andStictioneliminating Thread Tonearm Bearings,each made upof hundreds of 3microns thick twined Nylon 6.6/6 strandshorizontal and two Kevlar threads vertical

- twin Bonded five-layer Polymersandwich non-resonant Tonearm Beam

- one piece, Gold Plated Flexible PCB Tonearm Internal Wiring

- stainless steel main balancing counterweight and tracking adjustment weight with azimuth adjustment

- non--resonant, triple sandwich Cast Acrylic Main and Sub Plinth structure withimprovedintercoupling andcoupling tothesteel main-chassis for rigidity and structural support

- three new design adjustable feet with Resistive Felt Pads

- low frequency compliant, Tuned Silicone rubber integrated isolation system

- bespoke clear precision silicone rubber round'belt'–stable with temperature and humidity

- programmable Standby light

- 33/45 touch button speed selector

- non-resonant clearPolycarbonatedust cover with elegant Integrated hinges

- multi-voltage, Multi-plug Mains Power Adaptor–suitable for almost any regionor can beupgraded with the Challenger power supply